Offer

materials: structural steel, mild steel, aluminium, stainless steel

cutting range: 1500x3000mm

thickness range: up to 25mm

2D laser cutting of sheet metal is a metal processing technique that uses a laser beam to precisely and accurately cut various shapes from flat metal sheets. This process is computer-controlled and enables the creation of complex parts ensuring high surface quality.

2D laser cutting of metal sheets is widely used in the metal industry to produce structural components and machine parts. It is also used in the automotive industry, where body parts, engine parts, covers and other components are produced.

profiles: up to 140x140mm

pipes: up to 220mm

length range: up to 6000mm

3D Laser cutting of pipes and profilesis an advanced metal processing technology that allows accurate cutting of shapes and holes in three dimensions. It uses a computer-controlled laser beam to cut various shapes and patterns from metal pipes and sections, creating unique structural elements with excellent precision.

The technology is widely used in many industries, including construction, transport, automotive and energy industry. With its three-dimensional cutting capability, laser cutting of pipes and profiles enables the creation of complex and multi-faceted shapes that meet the highest quality standards. One of the key advantages of this technology is the high surface quality of the cut parts, which eliminates the need for additional material processing. The process is also extremely efficient and fast, which reduces production time and minimizes material waste.

welding robot: 900x2500mm | 900x4000mm

manual welding: TIG | MIG

Weldingis a process of joining materials by heating and melting them at the joining site with or without the addition of a binder. At our company, we offer both manual and automatic welding using a welding robot, providing robust connections at all levels of complexity.

Manual welding is a traditional method, perfect for welding components with unusual shapes or small series, where precision and flexibility are key.

Robot welding is an advanced technology that provides excellent repeatability and precision. Welding robots are programmed to perform precise welds, which allows for the production of large quantities of components with minimal risk of defects. This process is often used in the automotive, metallurgical and manufacturing industries, where speed and quality are key.

rectangular material: 90° – 500x335mm | 45° – 305x335mm

round material: 90° – ⌀335mm | 45° – ⌀305mm

Cutting steel with a band saw is a type of processing, aimed at giving the element a certain size and shape. It is a fast and precise method, which is why it is great for tasks requiring high quality from contractors.

The band saw is most often used for cutting profiles, sections, rollers or pipes. Devices of this kind cope well even with large and thick steel elements. They provide a high level of precision.

bending length: up to 6000mm

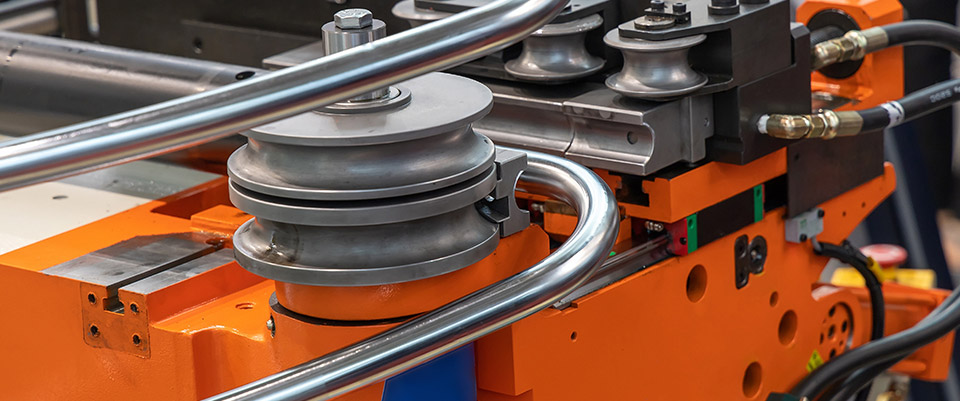

bending range: up to ⌀80x4mm

The process of CNC pipes bending is based on pernament change of the pipe’s curvature by controlled stretching and compression of the material in different sections of processed element. Appropriate adjustment of process parameters enables effective bending without adversely affecting the strength characteristics of the material. The CNC mandrel bending machine, which is used in our company, is based on the latest molding technologies and guarantees precision, repeatability and minimizes deformations in the bending area, while at the same time making it possible to create virtually any shape.

bending length: up to 6000mm

thickness range: up to 8mm

In addition to CNC pipes bending, we also carry out the process of metal sheet bending on a press brake. Bending of sheets is one of the most commonly used methods of processing, allowing for permanent shape change while maintaining the properties of materials. This is a popular machining process due to its ease of execution and great processing capabilities even for thick materials. Metal sheet bending includes operations such as bending, winding and profiling and straightening. This form of processing is used in many fields of industry, for example in the production of machine covers, fittings and more. It allows to obtain accurate dimensions and aesthetic appearance of manufactured details.

dimension range: up to 9500x2000x1000mm

The powder coating process involves the application of electrified powder paint particles to the metal surface. The formed powder layer is maintained on the surface of the painted part by electrostatic forces. It is a simple way to create a durable and aesthetic coating on a metal element or structure. The resulting coating, unlike coatings obtained in the process of traditional painting, is resistant to external factors such as moisture, UV radiation and temperature changes. It also guarantees resistance to corrosion and mechanical damage.

dimension range: up to 8000mm

Sandblasting is a technological process of cleaning or shaping any surface with an abrasive material in a stream of compressed air or liquid. Sandblasting allows to obtain a surface similar to sanded surfaces, but characterized by greater evenness and roughness required for painting. The sandblasting process allows to quickly get rid of corrosion and prepare elements for painting process.

Galvanization process is conducted to protect metal elements from corrosion. The process is to apply a layer of zinc to an element made of metal. One of the types of zinc plating is galvanizing, for which it is necessary to use electrolyte solutions, in which the whole metal element is dipped. Later, the solution is connected to the current. This creates a chemical reaction that allows zinc to bond with the metal. Hot-dip galvanizing, on the other hand, involves immersing the metal element in zinc heated to 450°C. This temperature makes it possible for zinc to bond permanently to the metal surface.

cutting and bending: ⌀6-32mm

stirupps and three-dimensional figures prefabrication: ⌀6-32mm

Prefabrication of reinforcing steel is a process focused on the production of reinforcements used in construction. Prefabricated products are manufactured based on the technical documentation provided by the customer. Steel prefabrication is carried out by our steel yard in Lwówek , using modern SCHNELL machine park. We offer cutting and bending services and production of spatial figures – U-shape, 3D figures.

Zbąszyń

Address

ul. Graniczna 19,

ul. Przysiółki 2

64-360 Zbąszyń

Sales Department

Powder Coating Department

Production department

Finance and Accounting

We are open

Monday to Friday between 7 AM and 3 PM

Saturday between 8 AM and 12 PM

Międzyrzecz

Address

ul. Reymonta 7

66-300 Międzyrzecz

Sales Department

Registration details:

KRS: 0000935334 | NIP: 9231735120

REGON: 385184154 | Share capital: 500 000,00 zł

Legal form: Limited liability company

We are open Monday to Friday between 7 AM and 3 PM

© All rights reserved

Production: Adstone marketing agency / Poznań